Dig-CirclE

High-performance, fibre-reinforced plastics (FRP) have a huge potential for lightweight constructions thanks to their properties, which has meant that their use in aerospace engineering as well as automotive engineering and wind turbines has been growing steadily for a number of years. This increasing use of FRPs presupposes a large-scale return of the end-of-life structures at the end of the utilisation phase that will have to be brought into the circular economy. Resources can only be used efficiently, energy saved and CO2 emissions minimised with digital and automated re-use, repair and recycling (RRR) processes in the circular economy. This results in the appearance of important business models with innovative FRP processes and products.

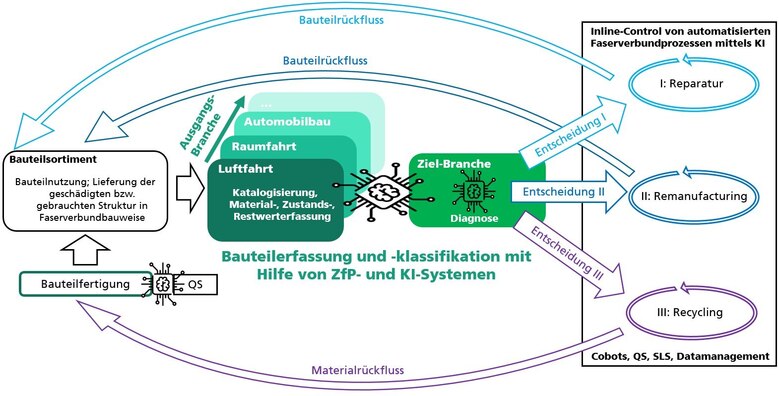

The Dig-CirclE project pursues the goal of improving the quality and eco-balance of the FRP processes and products. This can be achieved by digitising and automating the entire cycle – starting with the development, through production, right down to the renewed use, repair and recycling. Smart data management plays a key role here, identifying patterns and regularities by means of AI and enabling autonomous processes. RRR also makes use of digital twins. The result of Dig-CirclE will hopefully be an AI-based diagnostic system for an efficient circular economy of complex FRP structures for the automotive and aerospace industries. This system will allow the automatic analysis and assessment of structures/components, their automatic assignment to a material flow and automatic control of the RRR process.

The digital processes and the resulting homogeneous materials will be used in future in the production of new lightweight products and help cut costs.

The Dig-CirclE project is a strategic individual project through which the German Federal Ministry for Economic Affairs and Energy (BMWi) is supporting innovative technologies and solutions in the field of ICT.

Dig-CirclE is being coordinated by Elbe Flugzeugwerke GmbH. Further project partners include Hightex Verstärkungsstrukturen GmbH, LRP Autorecycling Leipzig GmbH, the Fraunhofer Institute for Machine Tools and Forming Technology IWU and Chemnitz University of Technology.

The Dig-CirclE project, together with the CircEcon project, contributes to a better standing of the Free State of Saxony on the global technology market for circular economy.